You will find pressure regulators in almost all the systems, no matter which pneumatic or hydraulic system you see. The main purpose of a pressure regulator is to control pressure. Pressure regulators have a variety of different and useful functions from keeping the system pressure below a particular limit to maintaining a particular pressure level in the part of the circuit and that is why they are required in most of the industries. Pressure controllers are even used in critical equipment like ventilators and anesthesia machines which require consistent flow of pressure at all times, failing which can cause fatal injuries or even deaths to patients. The core functionality of a pressure regulator remains the same no matter where it is being used.

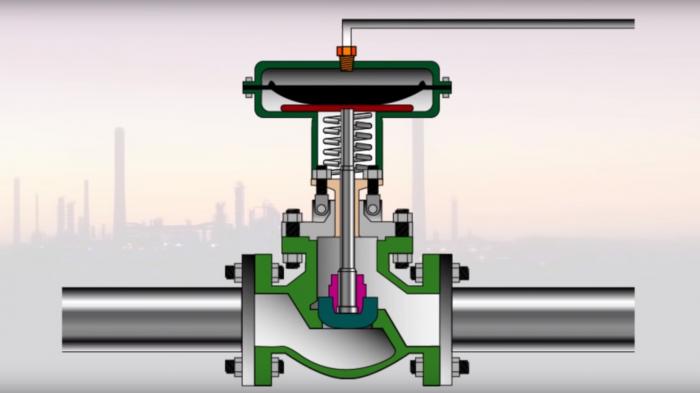

When it comes to the working of a pressure regulator, pressure regulators are actually valves that automatically cut off whenever the pressure of the flow of a liquid of a gas extends the permissible pressure. In a simple language, pressure regulator helps in changing a high pressure to a stable, usable and safe pressure which can be given to different applications

Applications of Pressure regulators in ships

A ship is a huge machinery in itself and since it carries man and material in bulk, there are hundreds of safety devices equipped in it to avoid unforeseen circumstances. One of the many safety devices equipped in a ship is the pressure regulator or pressure relief valve. Pressure regulators are usually installed in almost all the machinery systems that deal with high pressure hence ships are no different. To keep the designed working pressure under control in ships, these pressure regulators play an extremely important part thus minimising any chances of accidents and saving the loss of human lives and materials.

In a ship onboard, there are various pneumatic and hydraulic equipment installed which is why a pressure relief valve must be attached to these controls so that excessive pressure could be released whenever required and a state of equilibrium with respect to pressure could be reached. When it comes to the design of the pressure regulators, it is kept as simple as possible because these regulators are integrated in the ship’s machinery. The body of these regulators are made up of the compatible materials having high strength and which can easily operate on varied temperatures, air flow, fluid flow etc and are made with corrosive resistant materials as well.

Pressure regulator and Flashback Arrestors

When it comes to safety in ships onboard, pressure regulators and flashback arrestors are one of the vital components used to assist in the safe use of compressed gases at controlled pressure. We already know very well by now how pressure regulators work so the main aim of the flashback arrestors is to stop the reverse flow and flashbacks making the use of compressed gases like oxygen and acetylene safer for use in ships.

In an onboard ship, safety is considered to be the prime goal for everybody as the ship sails remotely in the sea where there is no help available whatsoever during emergency situations. In order to be double safe, all the pressure regulators and flashback arrestors must be replaced after every 5 years from the date of manufacture to prevent any type of wear and tear as well as leakage in the system. As per the recommendations by the various national safety authorities, the installation of flashback arrestors must be done both on the workstation as well as the cylinders for additional safety and periodical maintenance must be conducted from time to time for both pressure regulators and flashback correctors.